POLOLO also uses the “white gold”: report from the POLOLO specialist dealer lecture evening on September 10th in Berlin

Once again we had an evening of lectures that was interesting for specialist retailers in our Berlin POLOLO ShowRoom in September 2019. Some participants traveled extra long distances to hear the remarks from POLOLO managing director Franziska Kuntze and guest speaker Heike Hess, branch manager of the Association of the International Natural Textile Industry (IVN), to focus on leather, cotton, wool and hemp (all materials used by POLOLO for the shoe collection) and we would like to thank them very much for their participation!

Fiber training also recorded on video

Our concern was that Special features of organic cultivation and ecological leather production and to highlight the health benefits for the consumer. The aspects of occupational safety and social criteria for certified clothing and leather were also discussed.

As with our specialist dealer lecture evening on the topic “learning to walk” We have summarized the lectures in writing and will now inform our readers about each fiber in four individual blog posts, starting with cotton. We also recorded the lecture on film: You can find it on POLOLO on YouTube: “Training: Ecological cotton as a material for children’s shoes/textiles”.

Cotton – the white gold as the top dog of natural fibers

At the beginning of her explanations about natural fibers, Heike Hess talked about cotton, which POLOLO also uses to make shoes. This “white gold” to a certain extent is considered that “Top dog” among the natural fibers.

It was already cultivated in Egypt more than 9.000 years ago. In the 16th century it was considered a luxury good from Asia, until in the 17th century, in the course of the first industrial revolution, linen and hemp were initially replaced in England and cotton emerged as Mass product in Europe have spread out.

By the way, it was only in 2007 "Organic cotton" by a EU organic regulation been defined. Hess explained that the German term "Cotton" is rather misleading because the fibers come from bushes. In most languages the name is the Arabic word “qutn” [kutt:n] borrowed, seg “cotton” in English.

Cotton cultivation: India and China shared the top position

Cotton is grown in almost 100 countries: India and China share the top position in production, followed at a distance by the USA. The annual output is around 23 million metric tons. Approximately 2,5 percent of global agricultural land would be used for this. Only around 1,2 percent be organic cotton “controlled organic cultivation” (kbA).

In conventional cultivation, ie as monoculture, eleven percent of all pesticides or 16 percent of all insecticides would be used on cotton - a threat to biodiversity. Synthetic fertilizers and herbicides also caused soil and water pollution.

Within the organic cotton However, synthetic pesticides and fertilizers are deliberately avoided - alternatively, plant-based products and humus are used; Pests could be collected manually. Furthermore, it is crucial to select suitable locations and to avoid monocultures.

Aral Sea – a textbook example of unsustainable irrigation management

Hess showed the Aral Sea, which belongs to Kazakhstan and Uzbekistan, as a chilling example of extensive irrigation and soil salinization. What was once the fourth largest inland lake in the world is now largely silted up.

Hess explained that 10.000 to 30.000 liters of water are required for one kilogram of cotton in conventional cultivation. During surface irrigation, up to 60 percent of this evaporated. There was a threat of salinization and erosion of the soil. Furthermore, the sprayed ones were a burden Pesticides the drinking water sources.

Im Organic farming On the other hand, around 30 percent of the time rain-fed farming is used in order to avoid additional irrigation. Drip or furrow irrigation can save around 40 percent of water - so 7.000 liters of water are enough for one kilogram of organic cotton. The undamaged soil also stores much more water.

Use of defoliants for mechanized cotton harvesting

Machine harvesting in conventional cultivation requires that all of the bush's capsules ripen at the same time - this requires one Emergency maturity through the use of defoliants (nerve toxins – cf. “Agent Orange” in the Vietnam War), explained Hess.

The problem is that the capsules that are then opened absorb the poison. There will be one in the medium term Desolation of the soil – this also threatens biodiversity and groundwater.

In organic farming, defoliants are generally prohibited and the harvest takes place over a longer period of time manually.

Breeding genetically modified cotton with supposed advantages

The breeding of genetically modified cotton for the conventional cultivation initially promises a number of advantages: resistance to poisons, reduction in the use of chemicals, increased yield, but also an influence on fiber quality or lower water consumption.

Nevertheless, according to Hess, the use of genetic engineering in organic farming is prohibited: genetically modified plants are barren and did not deliver seeds for the following year, which meant higher costs and drove farmers into a debt trap.

Insects could also over time themselves Resistances and the introduction of genetically modified plants is an irreversible experiment. A sharp demarcation in field cultivation is not possible and GM plants could contaminate other areas.

Cotton cultivation: Lack of awareness of the problem when using chemicals

The social consequences of conventional cultivation, especially in connection with Poisoning through pesticides and paints, should not be ignored: Due to the prevailing poverty in many of the producing countries, there is no money for protective clothing.

The poor or inadequate labeling of the funds and that resulting from inadequate training and further education lack of awareness of the problem led to millions of poisonings, thousands of which were fatal.

As a rule, cotton is grown organically protective clothing made available. The employees received education, training and advice – as well as information in the local language. Farmers supported each other. The income situation is improved through bonus programs.

The downside of using cotton: child and slave labor as an extreme case

For the cultivation and processing of conventional cotton there are also excesses such as Child labor and sometimes even real slave conditions. For example, in “Sweatshops” Children already have to work ten to 14 hours without a break.

The work within the family is also often involved Dropping out of school accompanied. According to estimates, around 175.000 children were employed in the Indian cotton industry.

On the other hand, projects and initiatives tried to avoid child labor from the outset when growing organic cotton. Rather, you would school projects dedicated. They are also committed to paying fair wages.

Cotton is characterized above all by its skin-friendliness

The popularity of cotton, for example, is due to its skin-friendliness - according to Hess, it doesn't scratch and is beautiful breathable. It also has good absorbency.

Because of its heat and alkali resistance it is easy to wash and durable.

Cotton does not tend to mat and is mothproof. Their elasticity is higher than that of bast fibers and is more tear-resistant than wool or silk.

Cotton – ideal for the summer months

Cotton is refreshing and has a cooling effect (it hardly keeps you warm) and is therefore more likely to deliver Fabrics for the warm season. We at POLOLO like to use cotton as an alternative to leather, as this material is particularly elastic and light on the foot - it is ideal for children's feet, especially in the summer months.

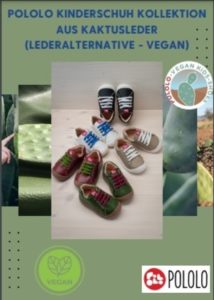

Photo: The new POLOLO “Uni” slippers made of cotton for a fresh feeling.